Research & development

Our Research and Development focuses on creating flexible packaging solutions for our customers and the needs of the circular economy that make products more attractive and easier to use.

Developing new innovations

In addition to supporting our divisions and product managers/application engineers as efficient service provider in customer projects, R&D also develops completely new innovations (in-house developments).

For this, our raw material experts are in regular contact with external development partners, such as suppliers, technical organizations especially in the regulatory and recycling area, institutes and universities for early identification of market trends, future needs and relevant technologies.

Constantia Flexibles has bundled the technical resources in the Competence Centers (Groupwide R&D) and Product Excellence Centers (Pharma R&D) who have

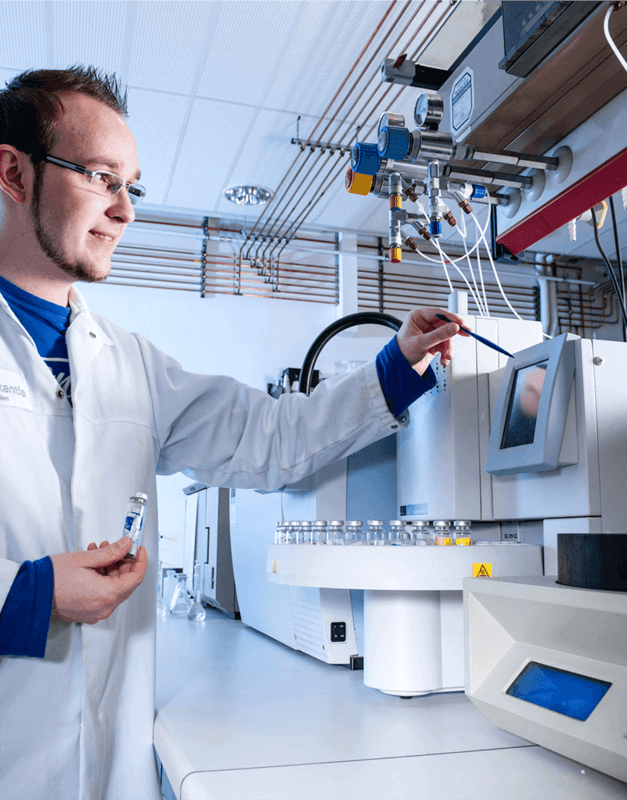

- State-of-the-art wet chemical laboratories with in-house lacquer development

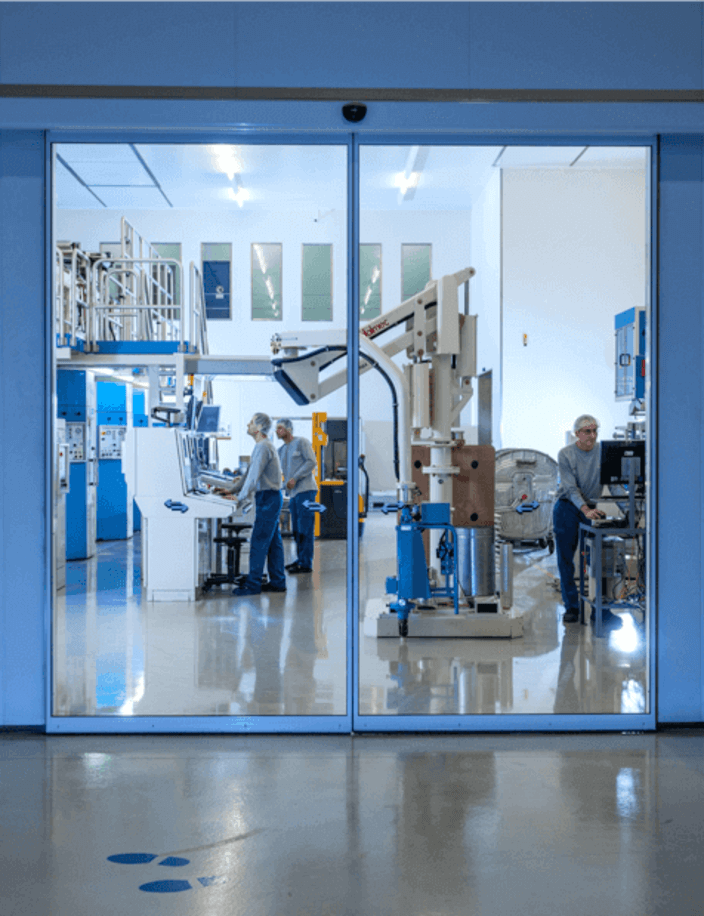

- Pilot plant facilities for blown and cast film extrusion, lacquering, adhesive and extrusion lamination, compound development, recycling of plastics and sealing & packaging trials

- Pilot blown film line, we can not only use to develop efficiently new sealing films, but could also produce needed volumes in the pre-marketing phase

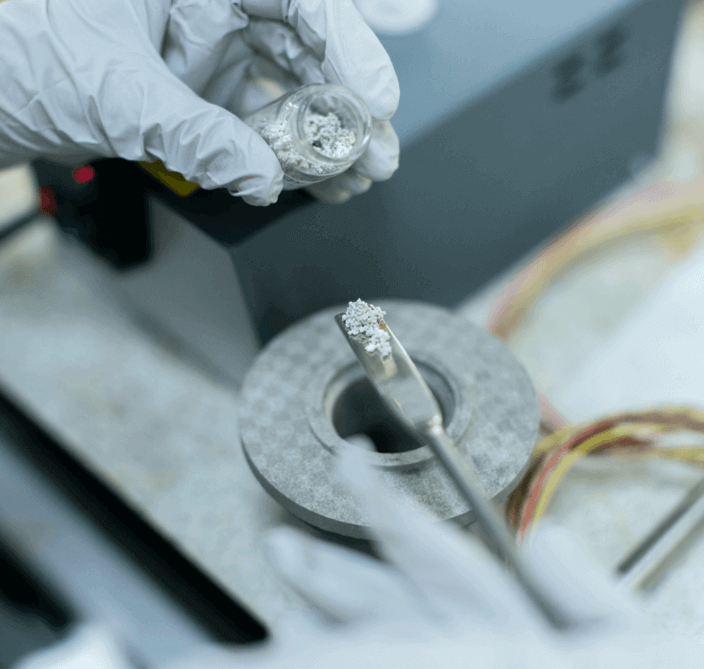

- A wide range of analytical and test equipment for checking properties of incoming raw materials and market samples/products up to pilot testing of various kind

- Deeper analytic capabilities to confirm compatibility of all our products with regulatory requirements

- Experts in the area of food law compliance and experts for all relevant raw material groups (aluminum, polymer resins, films, paper, lacquers, inks, adhesives, cold seal materials, additives, …)

- Patent department to perform e.g. FTO (freedom to operate) analyses