Innovative extrusion coating in focus

State of the art technology.

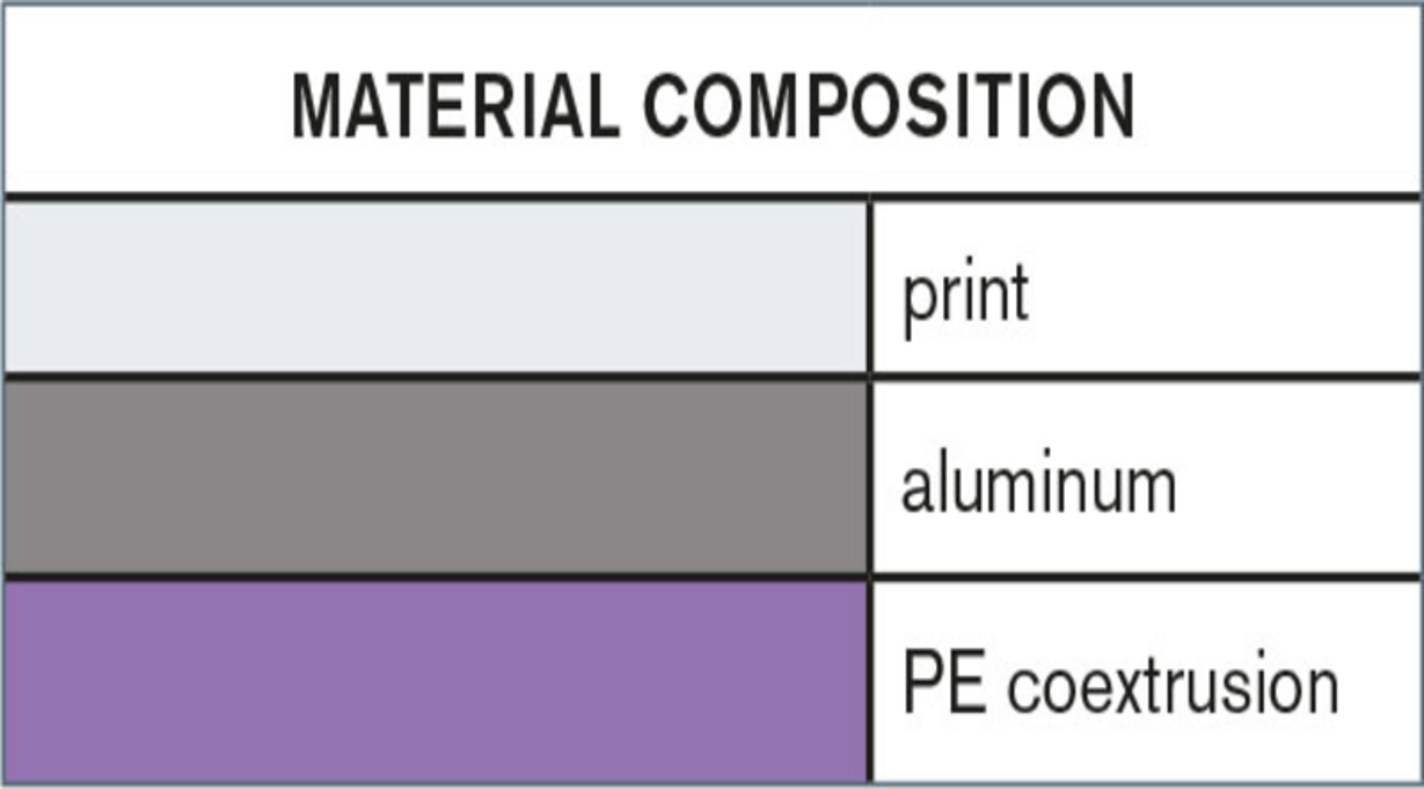

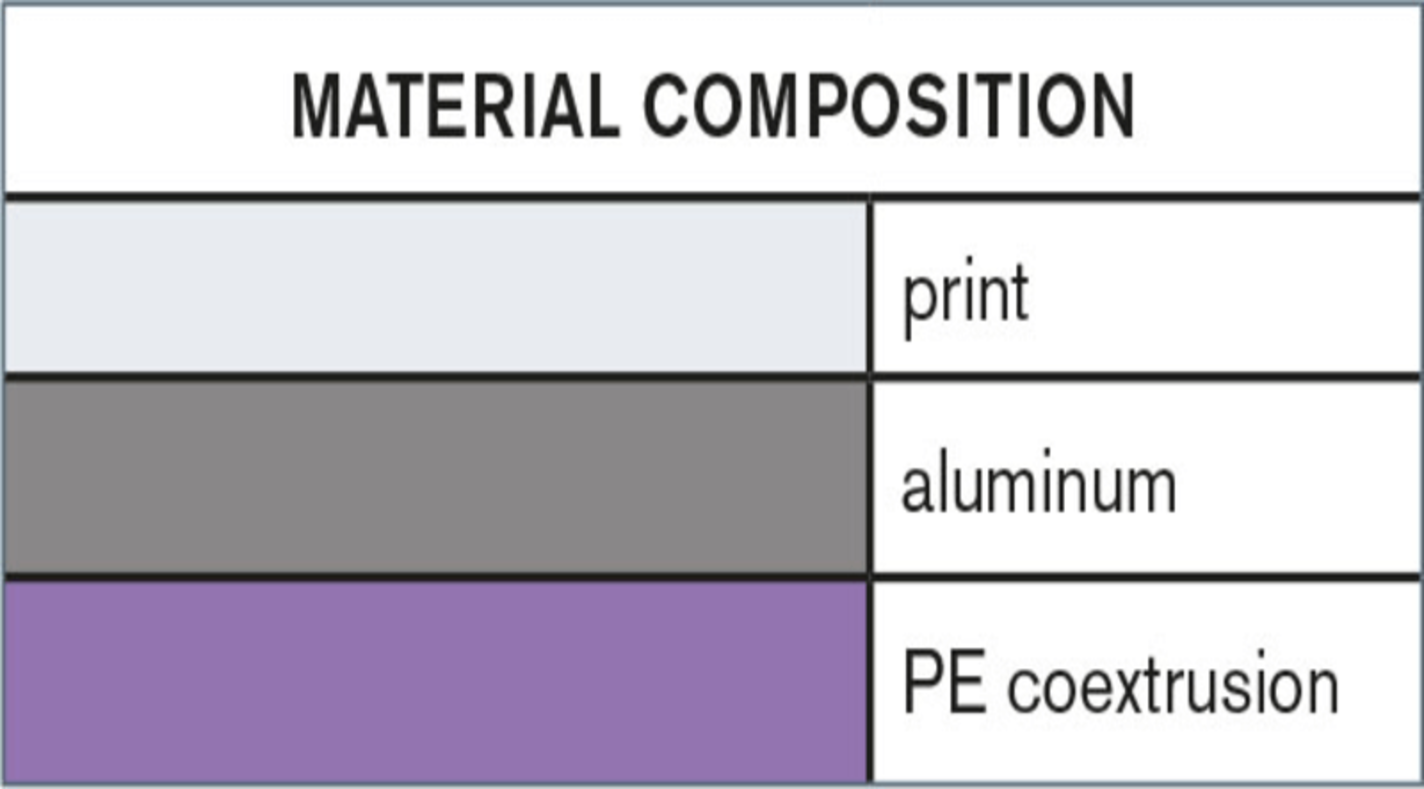

In 2002, the Coex-Family started producing CONSTANTIA PE-Peel as lidding for a famous yoghurt drink.

The sealing area of the cup was bumpy and a thicker sealing layer (thicker than heat seal lacquer) was needed which could balance the uneven sealing area.

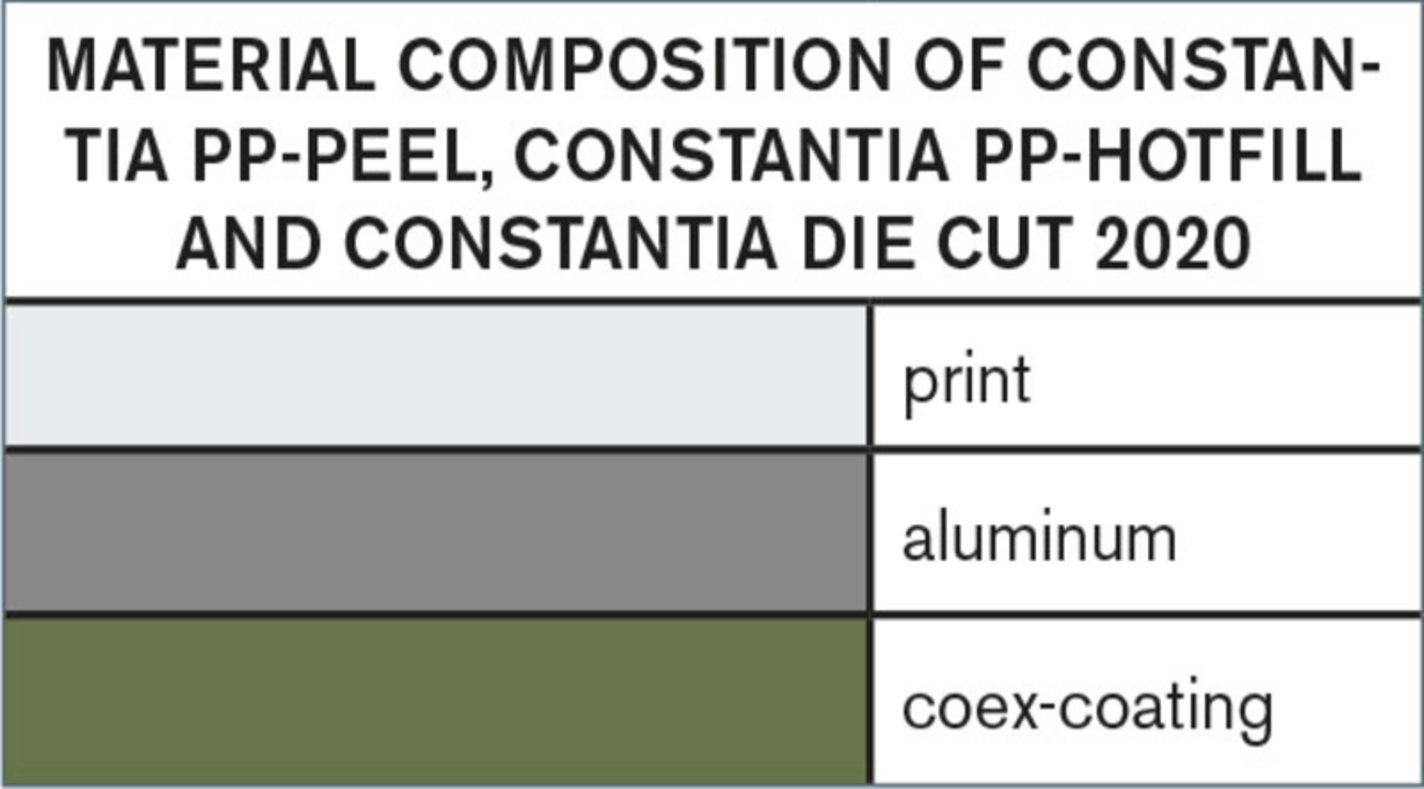

The second member of the Coex-Family was CONSTANTIA PP-Hotfill, which is an aluminum die cut lid with a Constantia Flexibles proprietary coextrusion coating. It has been developed for the hotfilling of cheese in cups which requires a very strong sealing of the lid on PP-cups. This offered numerous advantages, including a strong and continuous peeling, suitability for hot filling applications offers good seal through properties, if UV-Flexo printed, it is a solvent free solution, and offers high corrosion resistance. Additionally, it offers excellent rigidity for separation, sufficient thickness, height of separation dots, constant COF and can even be embossed.

Five years ago we developed CONSTANTIA PP-Peel which is a peelable sealing layer for comfortable opening of PP-cups. Due to the stiffness resulting from the coex-layer we could reduce the aluminum layer at same behavior.

CONSTANTIA PE-Peel, CONSTANTIA PP-Hotfill und CONSTANTIA PP-Peel are all aluminum die cut lids with a Constantia Flexibles proprietary coextrusion coating for sealing on PE- or PP-cups/bottles. They also offer specific advantages, including: a very wide range of sealing temperature (200-280°C) with excellent sealing integrity, easy and continuous peeling, good seal through properties, if UV-Flexo printed, it is a solvent free solution, offers high corrosion resistance, excellent rigidity for separation, constant COF, and is also available embossed or unembossed.

With the excellent properties and behavior of the Coex-Family we are able to offer our clients more sustainable products. Due to the reduction of aluminum (compared to conventional lidding with heat seal lacquer) we are able to reduce global warming potential up to 20%.

An additional coextrusion innovation is CONSTANTIA Die Cut 2020. It is a coextrusion coated die cut lid composed of a thin aluminum layer of 20µm and a proprietary Constantia Flexibles coextrusion coating and is sealable against PP-cups and available embossed or unembossed. While offering the same advantages as the CONSTANTIA PP-Peel it also offers up to 30% material reduction and aluminum reduction up to 50%.

Another member of the Coex-Family is Glas Sealing, which is a Constantia Flexibles solution for aluminum die cut lids or reel fed lidding sealing on glass and clay. It offers a very tight sealing and is also usable for induction sealing.

All of the showcased products are produced on our new extrusion lines at Constantia Teich which offer a state-of-the-art extrusion technology, steerage, drying options and significant lower energy consumption. Due to its technology it is possible to produce thin-layer-coatings especially for dairy packaging products and allows an increase of extrusion capacity which gives us the flexibility to extend our offer to the market.

Constantia Flexibles’ clever solutions honored by WPO and EAFA