From challenge to change: watttron and Constantia Flexibles redefine traditional lid sealing technology

How ring-heating enables seamless sealing of PP and aluminum lids on a single machine

In 2024, Constantia Flexibles tackled a core challenge in modern packaging innovation: How to efficiently seal different lid materials, specifically polypropylene (PP) and aluminum, onto PP cups using a single, streamlined system.

At the center of this effort was the continuous development of PPCover, a mono-material PP lidding solution designed for recycling and high performance. While PPCover fulfilled its environmental promise, integrating it into existing sealing technologies revealed a new technical hurdle: achieving reliable seals without compromising quality or efficiency.

Traditional sealing systems heat the entire sealing head and often introduce excess heat into the magazine and sealing unit. This can lead to issues like curling, where materials contract and deform slightly, posing a risk to product integrity. Although the issue was not widespread, Constantia Flexibles proactively addressed this potential complication, recognizing the importance of future-proofing their solutions.

By rethinking the sealing process and optimizing PPCover’s adaptability, the company advanced toward a versatile packaging system that supports both PP and aluminum lids on PP cups within a single, efficient sealing platform.

A breakthrough with watttron’s ring-heating technology

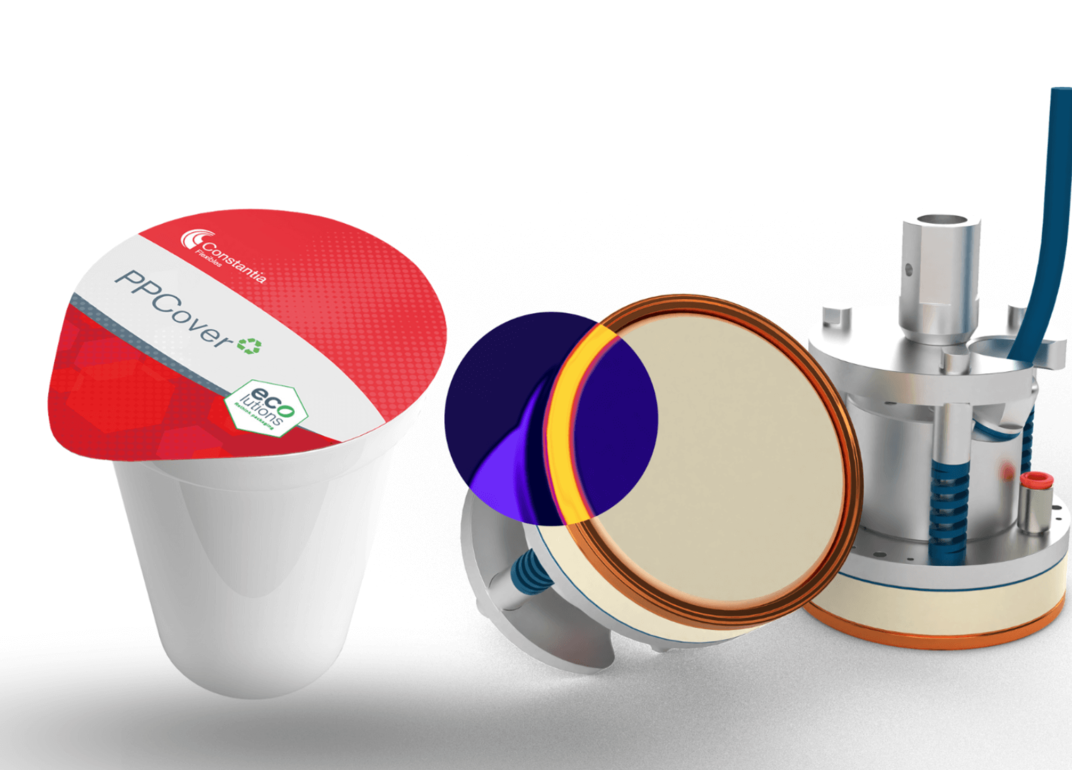

The answer came through a collaboration with watttron, a leader in precision sealing technology. watttron’s latest innovation, a sealing head that heats only the outer ring, offers a targeted and energy-efficient approach. By applying heat only where needed, the system minimizes thermal stress on the lid material, helping prevent curling while maintaining strong, consistent seals. Thanks to their low thermal mass and high power density, watttron sealing tools can heat up and cool down rapidly—typically at a rate of 10 to 20 °C per second. This enables the system to be ready for operation within seconds and to be safely switched off during production stops for energy-saving and safety purposes. The set temperature is maintained with high precision (±1 °C), ensuring consistent sealing performance. Overall, this approach offers a significant energy saving of 30 to 50 % compared to conventional sealing methods. Constantia Flexibles provided PPCover samples and technical specifications, and watttron conducted lab-scale sealing tests using their new system. The results were compelling: excellent peel behavior, strong internal pressure resistance, and seamless sealing performance for both PP and aluminum lids using the same equipment.

“We developed our ring-heating technology to deliver precise energy exactly where it’s needed – no more, no less. That precision not only improves quality and flexibility, and also contributes meaningfully to energy efficiency in packaging lines,” – Marcus Stein, CEO of watttron.

One system, many advantages

The universal sealing technology offers transformative advantages to packaging manufacturers. Enabling a single-sealing system to handle both PP and aluminum lids eliminates the need for separate setups or specialized machines. This streamlines production, reduces equipment complexity and costs, allowing faster and smoother transitions between packaging formats. Quality assurance also sees a boost. The system integrates seamlessly with 100% inspection capabilities, enabling defective cups to be detected and removed in real time. This ensures that the final product maintains the highest quality standards from start to finish.

As Claus Dworschak, Market Product Manager Die Cut Lids at Constantia Flexibles, notes, “This is a strong universal system for both aluminum and PP lids. A one-fits-all solution in dairy lidding. It simplifies operations and enhances quality—exactly what our customers need.”

Additionally, because only a portion of the sealing head is heated, the system offers potential energy savings, an essential factor in eco-conscious production environments.

Cross-divisional collaboration and continuous innovation

What began as a targeted R&D project quickly became a cross-divisional initiative within Constantia Flexibles. The Aluminum and Film Divisions joined forces with the company’s satellite plants responsible for lid punching to bring the concept to life. This collaborative effort demonstrates the company’s dedication to continuous innovation and building strong partnerships with leading machine suppliers like watttron.

Sealing smarter, sealing better

As consumer expectations and regulatory demands reshape the packaging landscape, innovations like PPCover and watttron’s precision sealing technology mark a major step forward. Together, Constantia Flexibles and watttron are not just solving technical challenges; they are shaping a smarter, more adaptable future for packaging. The partnership offers clear and measurable values for manufacturers and end users by delivering a universal solution.