Constantia Aluprint invests $315,000 to drive smarter, faster, and more reliable production in Mexico

At Constantia Aluprint, progress isn’t just a goal, it’s part of how we operate every day. That’s why our team in Mexico has committed $315,000 USD to a series of upgrades designed to make our plant more agile, more efficient, and better equipped to deliver the quality our customers expect.

This investment touches every part of our operation—from how we cut and inspect materials to how we solve problems on the floor. Here’s how it’s making a difference:

Precision where it matters most

We have installed a new Dimatra slitter in our rotogravure printing area, replacing an older machine and unlocking faster, more accurate cutting. This not only improves the quality of our output but also allows us to shift volume from other aging equipment - streamlining production and reducing bottlenecks.

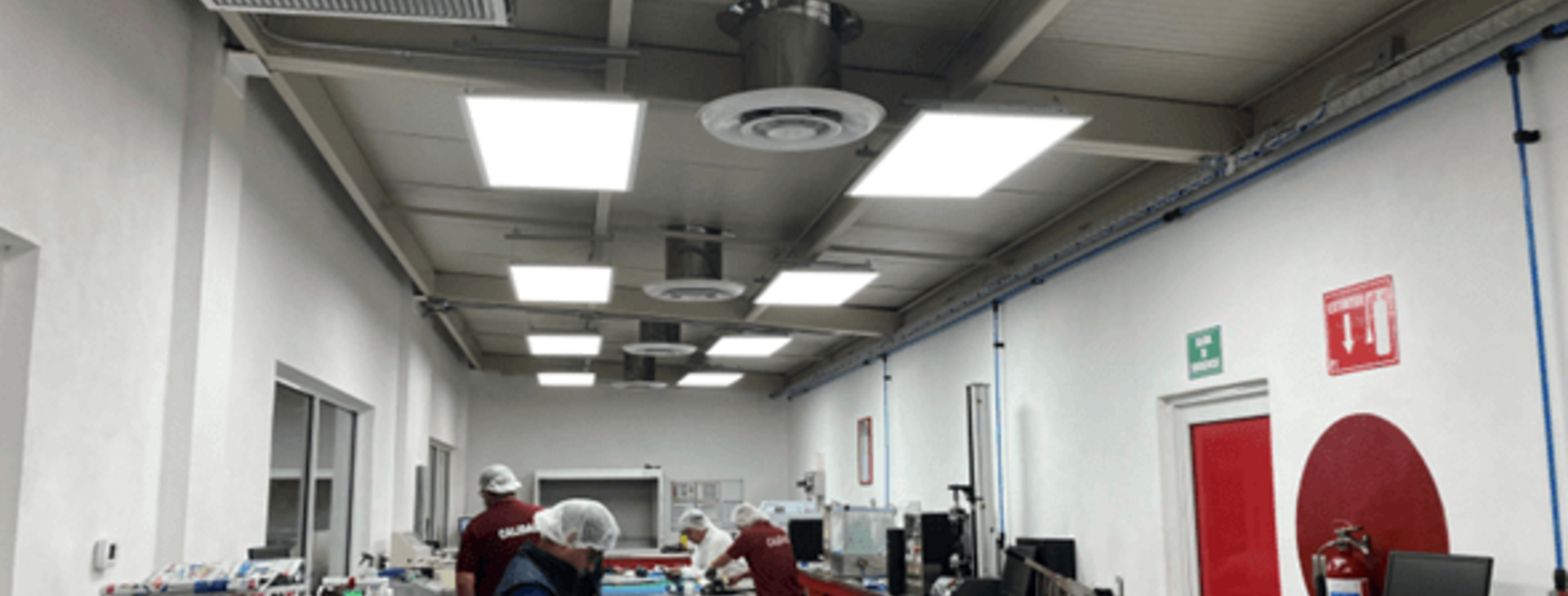

A lab that works as hard as we do

Our quality lab has been expanded and redesigned to support more advanced measurement tools and a better workflow. With more space and smarter organization, our teams can complete inspections faster and more reliably — ensuring every product that leaves our plant meets the highest standards.

Solving problems at the source

We have introduced ASPO modules — dedicated spaces on the production floor where teams can analyze equipment issues in real time. Instead of waiting for problems to escalate, we are tackling them head-on, right where they happen. It’s a smarter way to work, and it’s already helping us reduce downtime and improve consistency.

More room to grow — and handle waste responsibly

Finally, we have expanded the baling area in our flexographic printing section to better manage scrap material. This upgrade supports higher production volumes while reinforcing our commitment to responsible, efficient operations.

This investment reflects Constantia Aluprint’s commitment to continuous improvement and delivering high-quality packaging solutions to our customers. It’s not just about new machines or more space, it’s about creating a smarter, more agile production environment. With these upgrades, our teams can work more efficiently, solve problems faster, and respond to customer needs with greater precision and confidence.